Infusion Processes Built on Modular Design and Data Insight, Deliver the Consistency Your Wind Manufacturing Demands.

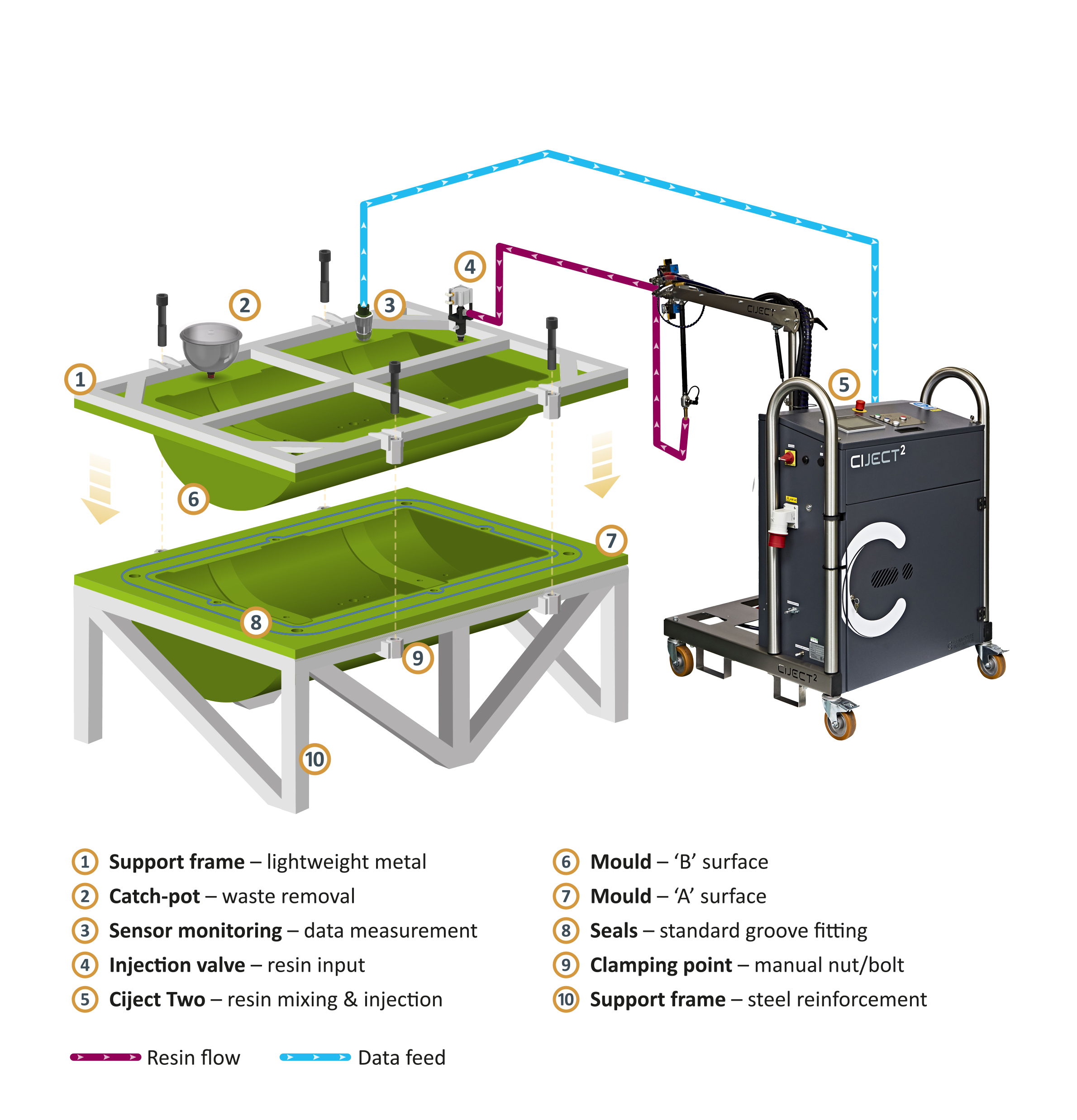

As global demand for renewable energy continues to surge, the wind sector faces a growing imperative: manufacture larger, more efficient components at scale, without compromising quality or productivity. At Composite Integration, we’ve responded to this challenge with an innovative, modular approach to our Direct Infusion process using our CIJECT systems, purpose-designed to optimise consistency, efficiency, and yield in wind blade and component production.

Simplifying the Complexity of Scale

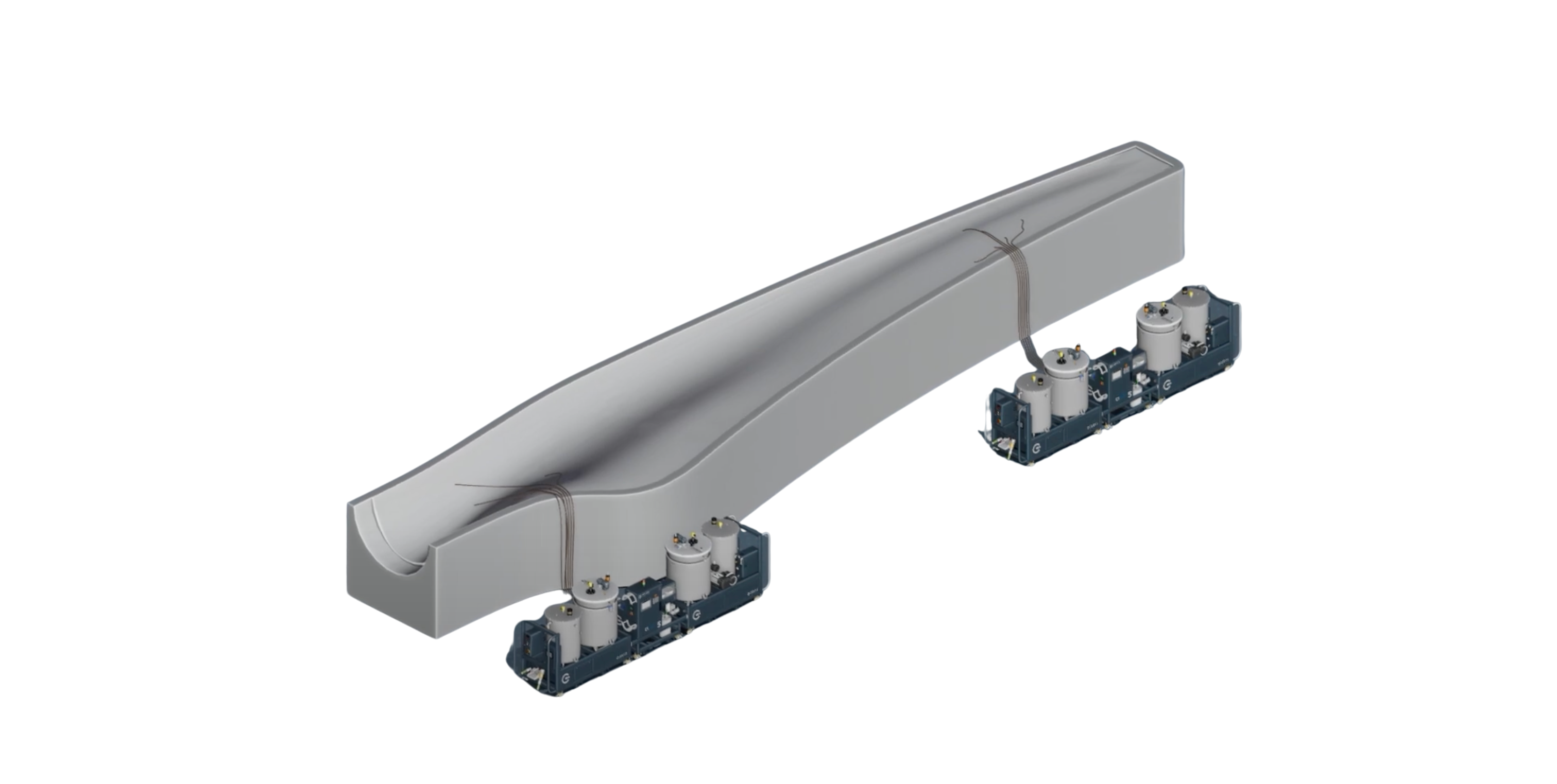

Direct Infusion, pioneered by Composite Integration, has become a key process in the production of composite structures such as wind blade shells, webs, and root spears. Yet, as component sizes increase, so do the challenges. Maintaining consistency across larger parts, managing resin delivery, and ensuring process repeatability can all become major bottlenecks.

The CIJECT range is engineered to bring simplicity to scale. From the outset, our systems are designed to be intuitive, operator-friendly, and minimally invasive during the actual infusion process. This is not just about automation, it’s about making smart decisions on behalf of the operator to ensure predictable results with minimal oversight.

A Modular Philosophy for Flexible Production

One of the biggest advantages of our CIJECT systems lies in their modularity. As manufacturers scale up their production or shift to different blade or component types, the flexibility to reconfigure or expand their equipment becomes essential.

Our modular CIJECT platform offers the ability to scale and integrate advanced features such as degassing modules or inline conditioning. Whether you're producing massive blade shells or smaller webs, the system can be tailored to fit your manufacturing strategy - today and as it evolves.

This modularity also aligns with the broader industry direction of decentralised, responsive manufacturing. Rather than relying on machines that have been designed for specific applications, wind manufacturers can now build and adapt infusion systems around their actual production needs, reducing capital expenditure and increasing responsiveness.

Degassing for Consistent Quality

When infusing, dissolved volatiles trapped within the resin can lead to significant defects including voids, dry spots, which in turn create a risk to quality, increase re-work and waste. Our CIJECT systems address this through advanced degassing modules, which significantly improve infusion consistency and eliminate one of the most common causes of composite defects.

Improving the precision of degassing and its measurement is visibly evident in the quality of the laminate.

Data Visibility and Remote Optimisation

At the core of our offering is a focus on data visualisation and remote analysis. The CIJECT systems are equipped with real-time sensors and intelligent monitoring software that provide operators, engineers, and managers with instant access to the most critical infusion parameters.

This visibility doesn’t just support quality control, it empowers continuous improvement. By understanding pressure trends, flow patterns, and cure progress in real-time, users can optimise infusion strategies across components, sites, or product lines. And because data is captured digitally, it can be analysed remotely, allowing both your team, and our support teams to identify, diagnose, and improve process variability in real-time.

In practice, this means fewer on-site interventions, faster problem resolution, and improved consistency across batches, even when scaling from R&D to full production.

Not Just Blades: From R&D to Root Spears

While wind blades remain the headline application, our CIJECT systems are proving equally effective in other areas of turbine production. Root spears or root segment components benefit from the same levels of process control, be it for infusion or for the injection profile of RTM component. CIJECT brings control, scalability, and efficiency to all elements of blade manufacture.

We also support the full journey right from R&D through to full scale production. For many manufacturers, this means starting with process development on a smaller scale and scaling confidently to full production with equipment and processes already optimised for their product and material strategy.

Cutting Waste and Rework, Increasing Yield

By design, CIJECT infusion systems help manufacturers cut unnecessary waste, whether it’s resin oversupply, dry spots requiring re-work, or variability that leads to batch rejection. Every module, from degassing to pressure control, is geared toward delivering consistent and complete resin infusion, reducing the need for post-processing and touch-up.

This translates to higher productivity and better yields. With fewer errors and a more repeatable process, operators spend less time troubleshooting and more time delivering finished parts.

Moreover, minimal operator involvement during the infusion itself means manufacturers can reduce labour costs while maintaining high standards. The system makes the critical decisions during the process, allowing staff to focus on set-up, QA, and process monitoring, rather than constant intervention.

Support That Scales with You

Beyond the hardware, Composite Integration provides a suite of support services that enhance long-term performance. Our technical support teams can remotely monitor process performance, help interpret infusion data, and guide users in optimising their process, even from across the globe.

This approach reflects our commitment to reducing variability, downtime, and cost through expert engagement. Rather than leaving clients to navigate ‘scale-up’ alone, we offer a partnership model grounded in continuous support and shared success.

A Better Way Forward for Wind

Wind energy is pushing the boundaries of size, output, and ambition. Manufacturing must evolve in line with this. Composite Integration is helping wind OEMs and Tier 1s take control of their processes, scaling production without compromising quality, operator efficiency, or sustainability.

Whether it’s reducing resin waste, cutting cycle times, or improving product consistency, our approach is built around one philosophy: there is always a better way.