As the demand for better, more efficient composites increases across industries, more manufacturers are turning towards innovative techniques that combine precision, versatility and scalability.

Resin transfer moulding is one such solution that addresses several of the challenges posed by legacy methods such as hand layup. Its appeal lies not only in the superior finish and structural integrity it delivers but also in its ability to accommodate different materials, complex shapes and large-scale production volumes. These benefits make it suitable for a wide range of applications.

What is Resin Transfer Moulding?

Resin transfer moulding, or RTM, is an advanced composite manufacturing technique in which liquid resin is injected into closed moulds that contain pre-placed fibre reinforcement materials. This process enables thorough fibre impregnation under pressure, creating precise and consistent composite parts at scale.

The Advantages of Resin Transfer Moulding

RTM offers several unique benefits over traditional closed mould methods. These include:

- Superior control of resin content and fibre placement for increased precision.

- Higher quality parts with minimal void content.

- A smooth finish on both sides of the part.

- The accommodation of large and complex shapes.

- The ability to use it with various materials.

- Maintaining quality at scale.

- Versatility for small batch and large-scale production.

- Lower material waste.

- Savings on labour costs.

- Potential for faster production times.

To find out more about embracing the advantages of RTM, see our guide on how to transition from hand layup to closed moulding.

Which Industries Benefit from RTM?

Thanks to its combination of strength, quality and versatility, resin transfer moulding is an ideal choice for industries where performance matters most. From precision-engineered parts to complex, lightweight structures, RTM delivers consistent results that meet exacting standards.

Industries increasingly turning to RTM include:

- Aerospace

- Marine

- Automotive

- Wind

- Defense

When component integrity is critical, RTM provides a reliable method for creating high-performance final products that stand up to rigorous expectations.

Resin Transfer Moulding Applications

Within these industries, RTM proves adaptable to a wide variety of specialised applications.

RTM in Aerospace Manufacturing

The aerospace industry must strike a careful balance between producing exceptionally precise parts that meet stringent standards while maintaining high production rates. This is where RTM and other innovative

processes come in.

These manufacturing techniques are ideal for creating lightweight yet robust and complex aerodynamic parts, such as wing sections or fuselage components, that can perform well under extreme conditions.

RTM in Marine Manufacturing

The transition from hand layup to closed moulding helps marine composite manufacturers remain competitive. RTM can be used in the boat-building process to increase efficiency, strength and sustainability while enhancing quality.

It allows for the production of large parts, including boat hulls and decks that require consistent quality and an ultra-sleek finish.

RTM in Automotive Manufacturing

Speed, efficiency and precision are essential in the automotive composites sector. RTM enables manufacturers to produce high-quality body panels, structural components and interior parts with consistent dimensional accuracy and excellent surface finishes – all while reducing costs.

Its ability to create lightweight yet strong components that can be produced with a quick turnaround and little or no trimming makes RTM an attractive choice for both high-performance sports car and mainstream vehicle production.

RTM in Wind Blade Manufacturing

Wind blade production is another area that relies on the ability to produce components that are stronger, lighter and more sustainable. RTM and direct infusion technology mark a major step forward in blade manufacturing, enabling the production of turbine blades with exceptional strength-to-weight ratios and faster cycle times.

The consistency and repeatability offered by resin transfer moulding help manufacturers meet tight standards, ensuring each blade performs optimally while allowing for higher throughput.

RTM in Defence Manufacturing

From ballistic armour and blast-resistant structures to helmets and specialised vehicle components, RTM plays a crucial role in creating high-performance composites built to withstand impact, temperature fluctuations and extreme conditions.

Offering an essential combination of durability, precision and design flexibility, resin transfer moulding is becoming an increasingly valuable composite production method for modern military applications.

Utilising Resin Transfer Moulding

Here at Composite Integration, we’ve worked with numerous partners across industries to create custom composite solutions that deliver superior quality and optimised efficiency.

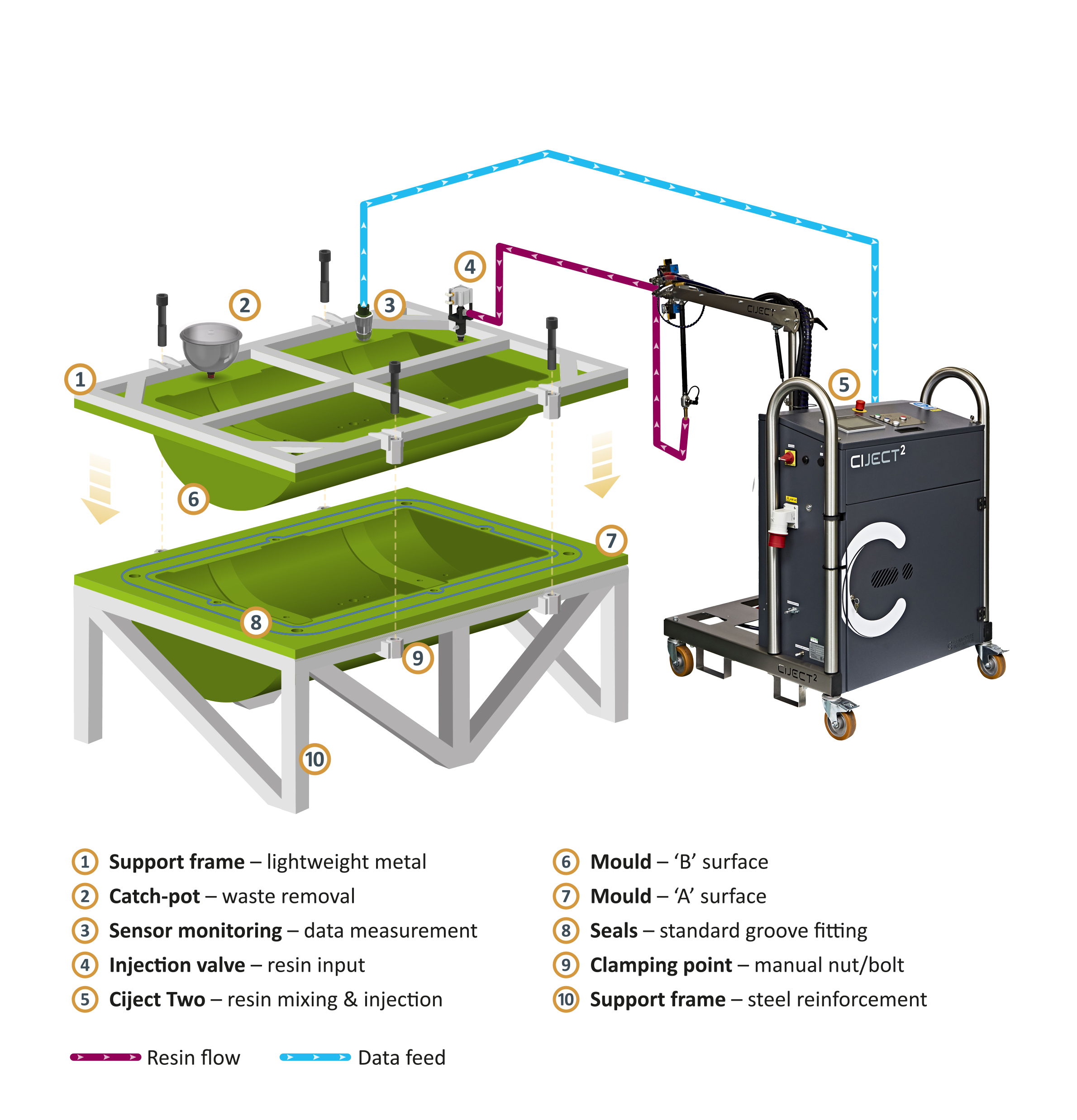

Our innovative CIJECT resin injection machines are designed to meet specific manufacturing needs, allowing you to incorporate RTM and other advanced techniques into your production processes.

If you’ve got a particular composite challenge or project in the works, please get in touch to find out more about how our experts and equipment can help.

-with-CIJECT-equipment-as-part-of-transition-from-hand-layup-to-closed-moulding.jpg)