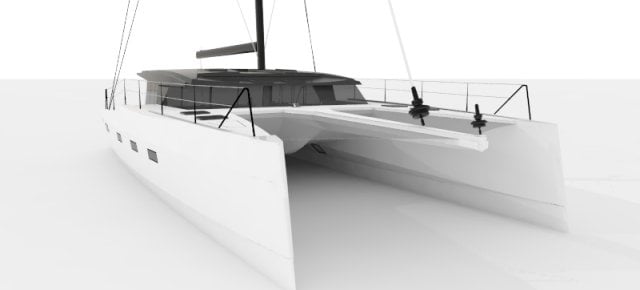

Cornish company Multimarine are the UK’s leading multihull design and construction specialists. Their new ground-breaking vessel, the Broadblue Rapier 550, is currently under construction at their Millbrook yard and is designed to combine exceptionally fast cruising with the capability to cover high mileages when sailing shorthanded. The finished boat will have a light-ship displacement of 9.5t with a full-load displacement of 15t. As with all catamarans, hitting target weight is crucial to maintaining performance.

For this reason it was decided that all the major mouldings be produced by resin infusion, giving a consistent fibre/resin ratio and minimum component weight. A further advantage of resin infusion was the possibility of producing the complex hull in a single piece thus saving time and weight and reducing the requirement for secondary bonded elements.

The infusion process was supervised by Multimarine’s Nick Hardy and Composite Integration collaborated with Falmouth Marine School’s Marine Innovation Service to provide technical assistance and support for this first large-scale infusion at the company; though a 15m catamaran was built using a similar process back in 2000, the BBR 550 is now the largest multihull in the UK to be infused in this way.

The Marine School’s own Ciject One injection machine was configured for use with epoxy resin and Alex Whatley (Falmouth Marine School), Stephen Leonard-Williams and Will Harris (Composite Integration Ltd) attended on-site to oversee the delivery of over 800kg of epoxy resin directly into the infusion process. Will did his student placement with Multimarine while still at University and it was nice for them to welcome him back in his new professional capacity.

The resulting hull is now being fitted-out and we look forward to seeing the finished boat!

Watch the video of ‘Building the Broadblue Rapier 550’: Video

Web:Multimarine